CONSTRUCTION QUALITY

- Home >

- CONSTRUCTION QUALITY

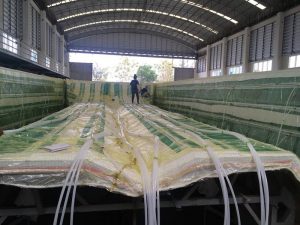

Vacuum infusion build

Ship building has been a human endeavour for over 4,000 years, but it is only recently that new technology has been applied to enhance quality. One of these technologies is vacuum extraction of the ‘sandwich’ of laminated layers, pulling the resins through the laminations resulting in a thinner panel, but stronger and with extended longevity. The resulting quality and improved weight and strength, are all parts of the excellent mechanical qualities achieved. The hull weight is kept under control, which in turns means optimal boat speeds.

PMG Shipyard started using this technology in 2013, and thus became one of the very first shipbuilders worldwide to have successfully introduced and utilised the ‘Total vacuum infusion technology’. Thereby, we could completely stop using plywood and other types of wood, like balsa, which is still often used by many of the large, mass production boat builders.

Team

Everyone onboard at managerial level, has several years of experience either from yacht racing or from yacht building, in Asia, Europe or the Caribbean.

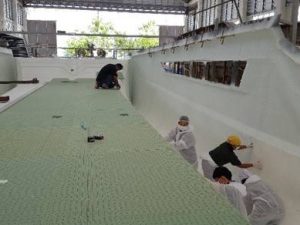

On the manufacturing side the large majority of the craftsmen are graduates from one of the maritime technical schools of Thailand, where they for 3 years have studied most of the secrets and techniques needed to master marine electrical installation, carpentry, fairing and painting, stainless steel and welding, fiberglass and other composite uses.

Location

Our yard is located directly on the beach with a dedicated launch ramp into the sea. The layout of each production area is designed to reduce walking distance, loss of time and promote efficient production.

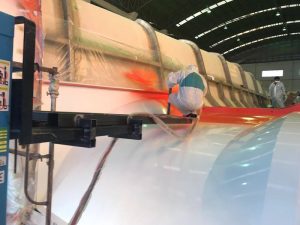

The production site is spacious, with lots of natural light which enables exact vision for detail work and exact colouring.

Having specialised work teams for each section on site, allows us constant monitoring and close supervision of ongoing work.

We have a unique freshwater test pool to ensure that each yacht is in perfect working and operating condition before the final launch at the launch ramp prior to handover to the new owner.

Suppliers and partners

For the construction, we use mainly multiaxial GRP (Glass Reinforced Plastic) Bisphenol A-Type epoxy vinyl ester resin with a vacuum infusing technique core sandwich. Most of our components are of Swiss and other European origin. Sika products are used for their respective duties whenever possible.

The stainless steel is exclusively 316L (marine grade) and are sourced from the most reliable suppliers.

All construction and building work are done in-house by our own staff, from the building of plug and mold to welding of steel parts and sewing of pillows. That allows us to trace each step of the building process and guarantee a high-end product.

For the outfitting of equipment and accessories of each yacht we rely on world renowned suppliers with whom we have long and trustworthy relationships.

Command – Control – Correct

You need to have the right team, the right high quality products, the right location, to produce a high end, complete product.

Never compromise on any of these items or on the process.